Businesses today are a part of a highly complex supply chain involving multiple suppliers and vendors located at different places across the world. When a disruption or bottleneck occurs in any part of the chain, it's often impossible to identify the source without a complete supply chain analysis. Without knowing the cause of the problem, it's not easy to achieve targeted sales and growth.

What is supply chain analysis?

Supply chain analysis is the process of evaluating every stage of a supply chain starting from the time the business acquires raw materials or supplies from its suppliers, to the delivery of final products to the customers. The purpose of the analysis is to determine which part of the supply chain can be improved or shortened to deliver the product more quickly and efficiently to the customers.

Why do businesses need supply chain analysis?

Supply chain analysis can help businesses optimize their processes to remove redundancies in the supply chain while helping create new value-added processes. This increases efficiency, reduces costs and minimizes risks. Efficient supply chain management is the backbone of a streamlined and cost-effective operation. When done right, it can save costs, enhance customer satisfaction, and give your organization a competitive edge.

Supply chain analytics help organizations across all industries make better, faster and more informed decisions about their business operations. It delivers real and lasting value for the companies that use it.

Examples of supply chain analytics

A few examples of supply chain analytics include:

Demand planning - using historical data and other factors to predict what customers will order

Sales and operations planning - manufacturing and/or purchasing the goods an organization needs to cover forecast demand

Inventory management - tracks inventory from purchase to the sale of goods and determines what stock it needs to replenish.

Benefits of supply chain analysis

Accurate supply chain analytics can help at every link in the supply chain by finding patterns and revealing other valuable insights.

- Uncover opportunities and highlight problems that operations leaders may not have seen coming. The ability to pinpoint existing supply chain risks and foresee future ones coming can have a big impact on the bottom line.

- Access to real-time analytics also helps firms gain a better grasp on their profitability, avoid stock issues, reduce late shipments and adapt to shifting customer preferences. This information helps businesses optimize their deployment of resources, and that leads to cost savings. In absence of this data, many of these decisions are left to guesswork and rely only on basic, historical data.

- Greatly reduce the amount of work required by staff to produce reports and analyses, and certainly cognitive analytics empowers employees beyond the data science team to pull results and understand them.

- As many organizations strive to be “data-driven”, supply chain analytics represent a critical step toward this goal. Put simply, company leaders can make better decisions when armed with detailed supply chain information and reports.

The different types of supply chain analytics

There are four primary supply chain data analytics that companies should consider right now to build more efficient operations that could save time and money.

Each of these supply chain analytics can increase the overall efficiency of business operations, which can lead to sizable cost savings.

-

Descriptive Analytics focuses on understanding what happened in the past by analyzing historical data. It can provide insights on key performance metrics, such as inventory levels, lead times, and delivery performance. Descriptive analytics can help identify patterns and trends in past supply chain operations, allowing organizations to make informed decisions about future strategies.

-

Diagnostic Analytics goes beyond descriptive analytics by identifying the root causes of supply chain issues. By analyzing data from different sources, such as suppliers, logistics providers, and customers, organizations can identify the factors that contribute to delays, disruptions, or quality issues in their supply chain. This can help them take corrective actions to prevent similar problems from happening in the future.

-

Predictive Analytics uses statistical models and machine learning algorithms to forecast future supply chain events. By analyzing historical data, organizations can identify patterns and trends that can help predict demand, inventory levels, and delivery performance. This can help organizations optimize their supply chain operations, reduce costs, and improve customer satisfaction.

-

Prescriptive Analytics takes predictive analytics one step further by providing recommendations on how to optimize supply chain operations. By using optimization algorithms and simulations, prescriptive analytics can help organizations identify the best course of action to improve supply chain performance. This can help organizations make better decisions and improve their overall supply chain efficiency.

How to conduct supply chain analysis

The above analytics should be used when conducting supply chain analysis. The basic steps of an analysis are:

1. Define Objectives and Scope: Start by clearly defining the objectives of your supply chain analysis. What specific goals are you trying to achieve? Determine the scope of your analysis, including which parts of the supply chain you will assess.

2. Data Collection: Gather relevant data from all stages of your supply chain, including suppliers, manufacturers, logistics, and distribution. Key data may include inventory levels, lead times, transportation costs, supplier performance, and demand forecasts.

3. Supply Chain Mapping: Create a visual representation of your supply chain. Identify all components, processes, and dependencies within your supply chain.

4. Performance Metrics: Define key performance indicators (KPIs) that are relevant to your objectives e.g, on-time delivery, lead time, inventory turnover, and cost per unit. Collect historical data on these KPIs for analysis.

5. Demand Forecasting: Analyze historical demand data and trends to make accurate demand forecasts.

6. SWOT Analysis: Perform a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) to identify internal and external factors that impact your supply chain.

7. Supplier Assessment: Evaluate the performance of your suppliers, such as quality, reliability, lead times, and cost. Identify strategic suppliers and assess their impact on your supply chain.

8. Process Efficiency: Analyze the efficiency of each supply chain process, from procurement to delivery. Identify bottlenecks, redundancies, and areas where process improvements are needed.

9. Risk Assessment: Identify potential risks that could disrupt your supply chain, such as natural disasters, geopolitical issues, or supplier dependencies. Develop risk mitigation strategies and contingency plans.

10. Technology and Automation: Evaluate the use of technology and automation in your supply chain. Determine if there are opportunities to improve efficiency through the implementation of new tools or systems.

11. Sustainability and Compliance: Assess the environmental impact of your supply chain and your compliance with relevant regulations. Identify opportunities to adopt sustainable practices and reduce your environmental footprint.

12. Cost Analysis: Conduct a thorough cost analysis to identify areas where you can reduce costs without compromising quality or service.

13. Stakeholder Feedback: Gather feedback from key stakeholders, including customers, suppliers, and employees. Use this feedback to gain insights into areas for improvement and customer expectations.

Tips and Tricks for a Visually Impressive Presentation

14. Action Plan: Based on the analysis, develop a comprehensive action plan that outlines the specific steps and initiatives needed to optimize your supply chain. Prioritize actions based on their potential impact and feasibility.

15. Implementation and Monitoring: Begin implementing the action plan, and closely monitor progress. Continuously assess the effectiveness of the changes and make necessary adjustments as you go.

Challenges of supply chain analysis

"Your supply chains generate big data. Big supply-chain analytics turn that data into real insights. In our view, the full impact of big data in the supply chain is restrained by two major challenges.

First, there is a lack of capabilities. Supply chain managers—even those with a high degree of technical skill—have little or no experience with the data analysis techniques used by data scientists. As a result, they often lack the vision to see what might be possible with big data analytics.

Second (and perhaps more significantly), most companies lack a structured process to explore, evaluate and capture big data opportunities in their supply chains."

Relying on spreadsheets, email and other point solutions to gather and review this critical data simply won’t cut it. Businesses need supply chain management systems that can track goods from raw materials to final delivery. They may also need a solution that can transform reams of data into useful reports and visualizations in order to get the most out of it.

In addition, a business needs to have strong processes in place to collect all the necessary data. Information from across the supply chain should be stored in a central database, which requires reliable integrations. Only with data flowing smoothly from all relevant systems can an organization understand the current status of and outlook for its supply chain.

Features to look for in a supply chain analytics solution

-

Connected: Any supply chain analytics effort starts with data, so it’s critical that the solution has access to all relevant sources of information.

-

Collaborative: Supply chain partners and customers are critical to your success. Cloud solutions make it easier than ever for these parties to exchange mutually beneficial ideas and information to enhance products or processes.

-

Comprehensive: Analytics software must provide extensive and thorough observations for an organization to realize the full potential of these tools, so the solution needs considerable functionality and the scalability to still provide immediate results as it handles increasing amounts of information.

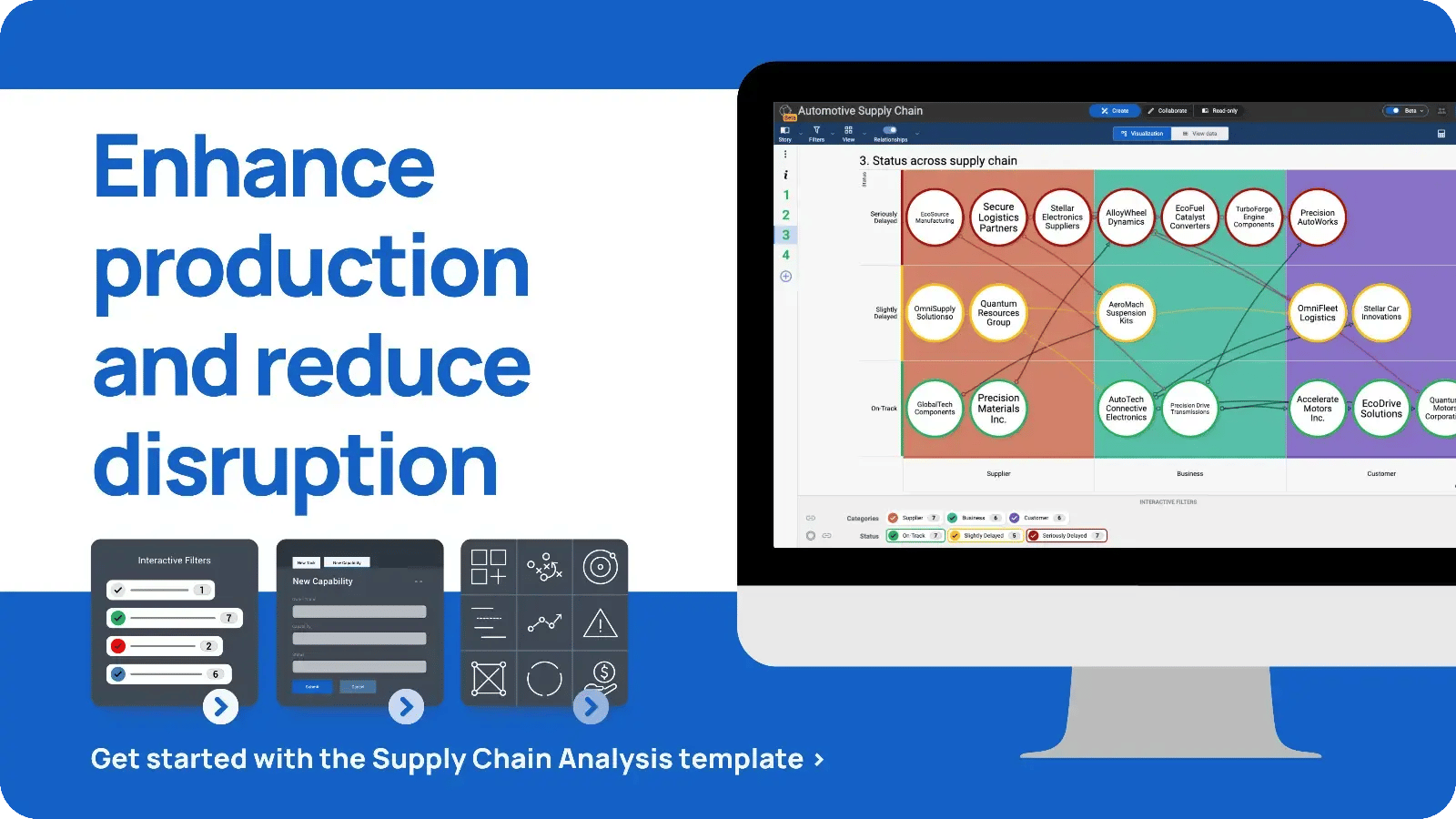

Manage your supply chain with SharpCloud

Supply Chains matter to all of us, whether it's managing risk, production, delivery, quality or supporting sustainable and safe growth. In NetZero terms it is vital to understand your supply chain to ensure suppliers are also heading towards the same NetZero Objectives as you.

Our Supply Chain Analysis template provides a full picture and understanding of the supply chain. You can map out the process from beginning to end and tie process owners and stakeholders to each stage, as well as keep track of activity status, visualize interdependencies and impacts.

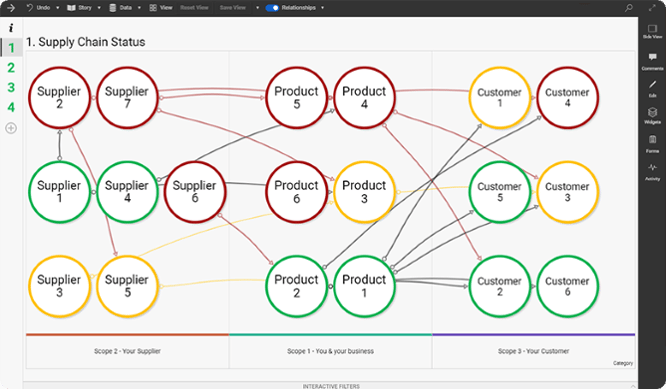

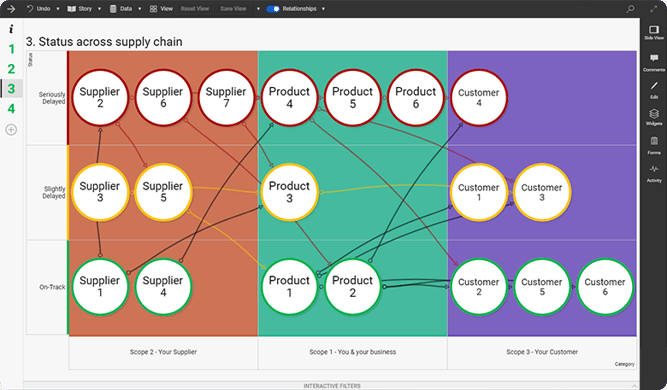

Understanding your supply chain includes definition of the following 3 scopes:

Scope 1: You and your business - what are you responsible for in your production?

Scope 2: Your supply chain - what is the impact of your suppliers on the rest of your supply chain?

Scope 3: Your customer - what do you do to manage the impact your product has on your customer base?

Examining your supply chain

You can see at a glance where the areas for concern are, and where your efforts are best invested and which products need your attention. This is real time data and can be changed dynamically so you always have an up to date picture of the the supply chain.

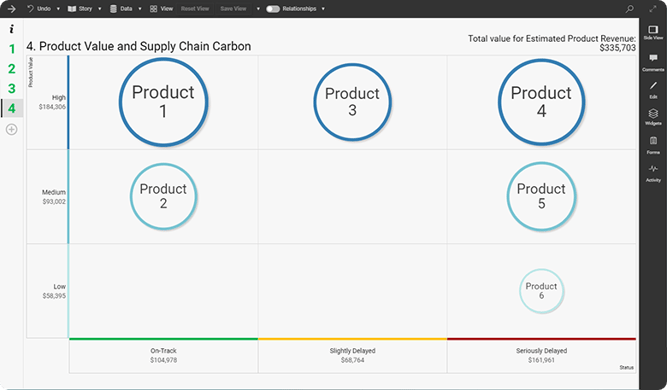

Cost / Impact and Value

The lifetime and value of a product may indicate whether you need to pursue supplier improvement, or aim to retire the product or service. The Low Value, High Status products will be the first for you to examine and consider phasing out.

You can use our template to answer questions like:

- What does the full scope of my supply chain look like?

- What is the status of the various stages and how will they impact future stages?

- What are the costs associated with potential delays?

- What are the potential risks?

Through smarter, more informed decisions, SharpCloud enables you to increase business agility, enhance production and reduce disruption within the supply chain.