As the world of manufacturing continues to evolve, it’s important for manufacturers to create and implement strategies that will set them up for success. Despite rising energy costs, nationwide skills shortage and economic inflation, UK manufacturers are making proactive business decisions that will help them shape the future.

In 2023 and beyond, there are a number of trends that manufacturers should jump on in order to add value and boost productivity while driving out cost and carbon to remain competitive. Here are four key areas that should be top of mind when creating a successful business plan.

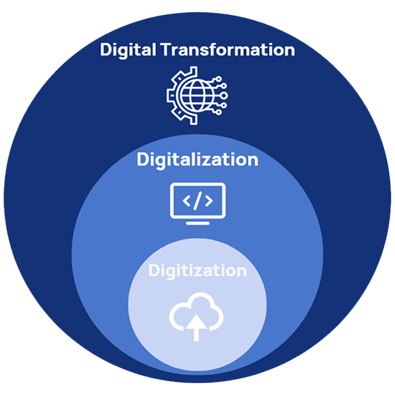

1. Embracing digital transformation in manufacturing

One of the most important priorities for manufacturers in 2023 is embracing digital transformation - specifically, digitalization, the first step of the process. Companies with higher digital maturity have shown greater resilience, as did those that accelerated digitalization during the pandemic.

This means leveraging Industry 4.0, a suite of new technologies that enable smarter, more efficient production processes across multiple industries. This includes cloud computing, artificial intelligence (AI), internet of things (IoT) devices, 3D printing and augmented reality (AR). These technologies allow businesses to increase efficiency and reduce waste by automating manual processes like ordering parts or scheduling maintenance checks on machines.

Robotics and automation are becoming increasingly sophisticated, allowing factories to streamline production lines and increase productivity. In addition, robots can be used for tasks that are too dangerous or difficult for humans to complete safely. By 2023, robots will be commonplace in factories all over the world.

By using technology to streamline processes, manufacturers can increase their output while reducing costs associated with labor, materials, and energy usage.

Companies with higher digital implementation tend to have increased supply chain visibility and are better able to adapt to supply chain challenges. Additionally, it could also accelerate the value mapping of suppliers and raw materials along with the impact of a shortage. This allows manufacturers to become more agile and responsive by quickly adapting to changing market conditions and customer needs.

Check out our blog on Keeping your Manufacturing Teams agile and connected

2. Adopting sustainable practices

Another priority for manufacturers is adopting sustainability throughout their processes. Manufacturers are progressing toward their environmental, social, and governance (ESG) commitments by making operational changes across their value chains.

Another priority for manufacturers is adopting sustainability throughout their processes. Manufacturers are progressing toward their environmental, social, and governance (ESG) commitments by making operational changes across their value chains.

Consumers today are demanding more sustainable products, meaning companies must ensure they have a responsible approach in how they source materials and produce goods. This involves minimizing waste, reducing emissions, and investing in renewable energy sources such as solar or wind power.

It also means instituting recycling programs or transitioning from traditional materials such as plastic or metal to eco-friendly alternatives such as bamboo or hemp. By making sustainability a priority now, manufacturers can position themselves ahead of the curve when it comes time for consumers to make their purchasing decisions in the future.

3. Data driven manufacturing

Data has always been an important part of any business, but data-driven manufacturing is set to become even more crucial in 2023. Companies are using data analytics to gain greater insights into their operations and improve decision making at all levels of their organization.

By collecting real-time data on every aspect of their business – from production times, supply chain to customer feedback – manufacturers can offer better products faster than ever before. Data analytics can help identify areas where improvements can be made as well as uncover new opportunities for growth that would otherwise go unnoticed.

By leveraging data analytics effectively now, companies can stay ahead of their competition while ensuring they’re making the right decisions moving forward into 2023 and beyond.

4. Talent retention

Finally, manufacturers continue to grapple with talent challenges that may limit the industry’s growth momentum. Despite a record level of new hires, job openings in the industry are still hovering near all-time highs, indicating substantial voluntary workforce churn. This prevailing workforce shortage, elevated by supply chain limitations, is reducing operational efficiency and margins.

Manufacturers are pursuing several approaches to strengthen their talent retention:

- A scarcity of talent is persuading more manufacturers to consider raising wages

- As the use of digital technologies rapidly increases, manufacturers are likely to offer continuous training to upskill the workforce, invest in startups to access new technology and talent, and collaborate with academic ecosystems to access digital skills

- Hybrid working and flexibility across operations. Manufacturers are actively seeking ways to rearchitect the work, the workplace, and the workforce to adapt to the broader shifts in the overall work culture and employee expectations.

The road ahead

Despite supply challenges, energy price volatility, labor shortages and an uncertain economic environment, the manufacturing industry is poised for a steady path of growth.

Amid these uncertainties, innovations and solutions pioneered in 2022 are expected to gain momentum in 2023, potentially altering tried-and-true business practices in the pursuit of growth and productivity.

The world of manufacturing is constantly evolving which means staying ahead of your competition requires an agile approach focused on technological advances such as digitalization coupled with sustainable practices driven by data analytics tools.

In the year ahead, manufacturing companies should consider the following:

- Increasing the utilization of digital technology to increase supply chain visibility, productivity, and connectivity with suppliers, partners, and consumers

- Growing focus on attracting and retaining talent through upskilling; reskilling; inclusion and providing flexibility where possible

- Implementing smart factory initiatives to achieve targeted business goals

Manufacturers who prioritize these trends will be well-positioned for success in 2023 and beyond by optimizing both efficiency gains while keeping sustainability top-of-mind throughout all operations processes and initiatives.

It is essential that companies keep these priorities at the forefront if they hope to remain competitive in today’s market place going forward into the future.